Plastic injection molding is one of the most popular fabrication processes used to create plastic components. Injection molding allows manufacturers to create intricate components quickly and efficiently with an exceptional degree of accuracy and repeatability.

During the plastic molding process, melted plastic is injected into a prefabricated mold under pressure. The pressurized plastic is forced into every crevice and then allowed to cool into the desired shape. Injection molding creates products with a smooth, clean finish that requires little to no additional processing.

What Are Some Considerations for Plastic Injection Molding?

Financial Considerations

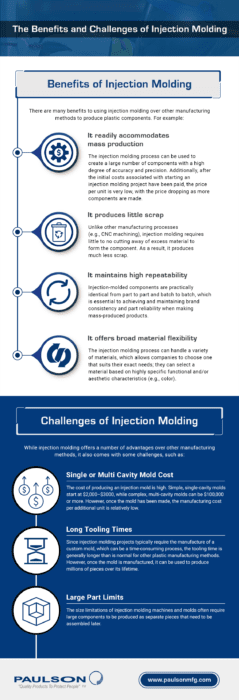

Plastic injection molding is a front-loaded expense. Injection-mold tools must be designed to meet the exact specifications of your product. Once you have invested in developing a quality mold, you save significantly during production. Plastic injection molding allows for higher volume production with greater speed, precision, and repeatability than traditional machining methods. The molding process is highly automated, reducing labor expenditures and the potential for human error.

Production Quantity

Determine the number of parts you need to produce to break even on your investment. Take into account all the costs associated with your project from design investment to distribution costs. With this data, you can determine the production numbers needed to make injection molding a cost-effective option.

Design Considerations

Design your product with the injection molding process in mind. You can produce higher-quality parts by reducing design complexity and minimizing the number of parts in your product. Design your mold to avoid poor gate placement, thin channels, and other design flaws that result in poor product quality.

Production Considerations

With well-designed mold tooling and hot runner technology, you can cut down on cycle times and enhance overall production efficiency. Assembly should be minimized or eliminated from your design, if possible. By removing assembly work, you improve your product quality while minimizing time and labor costs associated with assembly processes.

What is New with Plastic Injection Molding?

Plastic injection molding is an evolving industry, and recent advances in technology help keep this popular fabrication at the forefront of the manufacturing sector. Some of the latest

- Micro-molding: Used to create extremely small, precise components.

- Printed Injection Mold Tool (PIMT): Allows manufacturers to create custom 3D printed injection molds and retrofit existing molds with 3D-printed inserts for simpler customization and more cost-effective tool making. PIMT is ideal for prototypes and small-scale production, as 3D printing materials are not capable of withstanding consistent exposure to extreme plastic melting temperatures.

Why Does Paulson Utilize Plastic Injection Molding on our Products?

Injection molding is a versatile and cost-effective process that creates quality plastic products for many industries. Paulson Manufacturing uses the latest injection molding technology to produce superior quality safety equipment for firefighters and industrial personnel. Our molds are custom designed to create solutions that exceed stringent industry safety standards. In addition, Paulson Mfg. designs and builds all injection mold tooling in-house.

- Detailed Features/Complex Geometry: Our injection molding process injects melted plastic into the mold at extremely high pressures, creating accurate results unmatched by other molding processes.

- High Efficiency: Once we have designed and created an injection mold to your specifications, the rest of the highly automated molding process is quick and efficient.

- Enhanced Strength: Our process enhances products by utilizing custom formulated materials to exceed specifications and bring additional value to the products.

- All Electric Molding Machines: Higher precision and more energy efficient.

Innovative Protective Equipment Solutions by Paulson Manufacturing

At Paulson Manufacturing, we understand the importance of producing equipment that meets stringent design specifications and rigorous industry standards for quality and safety. We use the latest injection molding technology to create superior products for our customers in the industrial, manufacturing, medical, defense, and firefighting sectors.

To learn more, check our blog on plastic injection molding, or contact our experts today to request a quote for your next project.