Pt. 3 of 3: Arc Rated GORE® PYRAD® Fabric Technology

In our first installment of this 3-part series, we discussed some of the key trends the electrical PPE market, and how GORE-TEX Professional Fabrics & Paulson Mfg. employ advanced technology to improve electrical PPE. Arc flash suits that are lighter weight and more breathable, and face shields that provide enhanced visibility are examples of these improvements and this is driven heavily by feedback from the end-users.

In the second installment, we discussed the specific technology used in Paulson’s next-gen arc flash face shields.

For our third and final installment of this series, we’ll take an in-depth look at the technology behind Arc Rated GORE® PYRAD® Fabrics, specifically the next-gen single-layer 40-cal suit.

Need in the Marketplace for a Lighter, More Comfortable 40-cal Suit

Performing tasks exposed to high incident energy with a risk of arc incidents of up to 40 cal/cm² is often physically demanding and requires highly reliable personal protective equipment. The standard compliant 40-cal (CAT 4 NFPA70E / CSA Z462) switchgear suit needed to protect electrical workers are often heavy and based on multi-ply fabric systems. The multi-ply fabric switch suits result in bulkier solutions that lead to restricted freedom of movement and discomfort. This discomfort leads to less wearer acceptance and reduces likelihood to wear the PPE properly.

Following intensive research and development, and combining proprietary technologies, GORE-TEX Professional has developed the only single-ply CAT 4 (40 cal/cm²) and lightest weight (less than 10 oz/yd²) functional fabric for designing the new Arc Rated GORE® PYRAD® suit. High arc protection and the benefits of lightweight, high breathability, and freedom of movement are incorporated into all garment elements. With this innovation from GORE®, electrical consultants, contractors, and electrical and instrumentation (E&I) technicians exposed to arc incidents up to 40 cal/cm² no longer must compromise protection over comfort.

The Science Behind Arc Rated GORE® PYRAD® 40-cal Suit

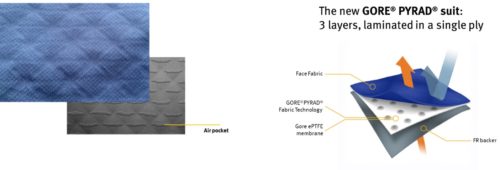

The Arc Rated GORE® PYRAD® fabric technology used in 40-cal switchgear suits consists of four main functional components engineered into a durable single-ply material that interact with each other.

These components consist of:

- Nylon Outer Shell: Brings the benefits of the versatile nylon material, such as easiness to dye into different colors, color fastness, tensile strength, and excellent abrasion and wear resistance.

- Protective GORE® PYRAD® Fabric Technology: Made up of countless little reactive dots, this breakthrough technology is self-extinguishing. This adds inherent and durable heat, flame, and arc-resistant properties to non-flame retardant textiles such as nylon, while leveraging properties that have traditionally been difficult to achieve with conventional FR textiles.

- GORE® ePTFE Membrane: The highly breathable and thermally stable GORE® ePTFE membrane provides the required strength, flexibility and mechanical integrity at extremely light weight and thickness.

- Flame-Retardant Backer: This textile provides thermal stability, reduce burn caused by heat transfer and contributes to optimize the wearing comfort.

Integrating these four key components has produced fabric technology with a unique structure that incorporates air pockets between the layers. This enhances both thermal protection and wearing comfort.

How Does this Fabric Technology React to an Arc Flash?

During an arc flash exposure, GORE® PYRAD® fabric technology (dots) rapidly reacts to the heat even before the outer shell starts to burn. The reaction of the dots causes them to expand by a magnitude of more than 10x higher than its original size. This forms a stable insulating protective shell of carbonaceous char, with the face fabric (without melting or dripping) blocking the heat transfer to skin, stopping flame propagation, and blocking heat flow from the arc flash exposure. As an additional protective mechanism, the air pockets between GORE® ePTFE membrane and flame-retardant backer expand by adding more air to form an additional insulating layer that blocks heat transfer to the skin. After arc exposure, the fabric exhibits best-in-class mechanical integrity with no hole formation to the innermost layer.

Key Features & Benefits to the End-User

Based on rigorous scientific testing, the Arc Rated GORE® PYRAD® 40-cal suit has been developed with real-work situations in mind, so that hard-working professionals in challenging environments can stay protected, and simply focus on their important work.

Compared to multi-layer switchgear suits, the key benefits for wearers of garments made of the single-ply Arc Rated GORE® PYRAD® Fabric include:

- High arc protection

- High freedom of movement

- Light weight

- Reduced bulk

- High breathability

- Protection against Incidental flame exposure

The fabric technology provides a reliable protection above and beyond ASTM F1506 requirements with an arc rating ≥40 cal/cm² (ATPV), allowing fabric elements of the switchgear suit to with NFPA 70E (USA) and CSA Z462 (Canada) CAT 4. It is also up to 20% lighter than competitive products, allowing for a thin, less bulky, yet robust garment with easy donning and doffing. The unique fabric structure not only enables high levels of protection against thermal hazards but allows for more functional garment designs with a high freedom of movement that wearers can feel.

The material used in the Arc Rated GORE® PYRAD® 40-cal suit is a very breathable fabric that keeps the wearers dry and comfortable on the inside while performing highly physical tasks without compromising thermal protection required in case of an electric arc flash incident.

To learn more about the rest of standard compliance of this new fabric technology visit the GORE-TEX Professional Website here: https://www.goretexprofessional.com/technologies/gore-pyrad/work-wear-arc-rated-garments-40-cal-suit

Leaders in Arc Flash Safety

This wraps up our 3-part series on the latest innovations in arc flash protection fabrics from GORE-TEX Professional Fabrics and next-gen arc flash face protection from Paulson Mfg. To learn more, please contact us today.