In high-temperature industrial environments — such as foundries, steel mills, glass manufacturing, and other extreme heat applications — workers rely on specialized personal protective equipment (PPE) to stay safe from intense radiant energy. When it comes to the best possible protection against radiant heat, there is one material that stands above the rest: gold.

The Science Behind Gold’s Exceptional Heat Reflectivity

Gold’s effectiveness as a heat reflective material is rooted in its remarkable optical properties. It reflects up to 99% of infrared radiation — the very type of radiant energy most responsible for heat transfer in high-temperature environments. Beyond reflecting infrared radiation, gold coatings are also designed to optimize visible light transmittance for the best possible view while working. Unlike other coatings, gold doesn’t just scatter or absorb heat; it actively redirects it away from the wearer. This high level of reflectivity dramatically reduces the thermal load on PPE, keeping workers cooler and significantly lowering the risk of heat-related injuries.

Not All Gold Coatings Are Created Equal

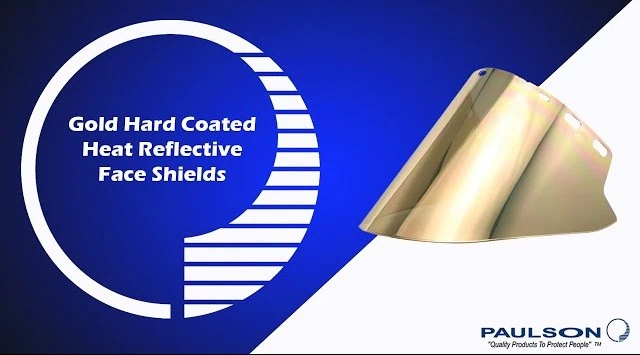

Many manufacturers recognize gold’s advantages and apply gold coatings to their face shields and visors. However, the real difference lies in how that gold is used. Paulson sets itself apart by applying a coating of pure gold to our heat reflective face shields.

Some competing products use diluted gold alloys or thin sputtered coatings that incorporate other metals. While these methods may lower production costs, they come with trade-offs: reduced heat reflectivity, less durability, and the risk of coating degradation under prolonged heat exposure. Gold alloys and thin layers can tarnish or wear out over time, compromising the very protection they are meant to provide.

One major issue is thermal cycling: the repeated exposure to intense heat followed by cooling. When a face shield is subjected to rapid temperature changes, the material naturally expands and contracts. Coatings that are not pure gold — especially those blended with other metals or applied in ultra-thin sputtered layers — often fail to flex with the substrate. Instead, these mixed or layered coatings develop micro-cracks over time as they struggle to keep up with the substrate’s thermal movement.

These cracks don’t just affect the shield’s appearance; they directly compromise its ability to reflect radiant heat. Once the reflective layer fractures or peels, hot spots form where heat can pass through, putting the wearer at risk of heat stress or burns.

Why Paulson’s Pure Gold Coating Is Superior

In contrast, Paulson’s process uses a carefully controlled, pure gold deposition technique. This ensures a uniform, durable layer of gold that maintains its exceptional reflectivity even after repeated exposure to extreme temperatures. Because our gold layer is pure gold, it does not degrade as quickly, ensuring that workers maintain maximum protection for longer periods. This translates to fewer replacements, lower lifetime PPE costs, and most importantly, better safety on the job. Beyond just the coating itself, Paulson also engineers its gold face shields with precision optical clarity and robust impact resistance, ensuring that workers don’t have to trade visibility or physical protection for heat defense.

Commitment to Safety Through Pure Gold

In the demanding world of industrial heat hazards, small differences in product design can mean the difference between staying safe and facing serious injury. Paulson Manufacturing’s commitment to using pure gold rather than alloys is more than a technical detail — it’s a reflection of our philosophy: that worker safety should never be compromised by cost-cutting shortcuts.

By choosing PPE that harnesses the full, unmatched heat reflective power of pure gold, industrial workers can be confident that they are investing in the very best protection available.